Our research activities in the fields of micro-turbomachinery components and cycles, basic and applied heat transfer, and measurement techniques development is supported by range of laboratory equipment. These capabilities are also available to provide service to the industry and other academia members upon demand:

To obtain quotations for the available laboratory services, please contact us.

Custom Atlas Copco ZT315-8.6-50VSD Screw Compressor

capable of continuously delivering up to 0.9 kg/s of air at pressure ratio of up to 1:7, while operating in closed loop with inlet pressure in the range of 0.3-1 bar.

Capstone C65 ICHP Micro-Turbine

CHP unit capable of delivering 65kW electric power and recovering 120kW of heat. Used towards studies of optimal dispatch and smart-grid control.

Phoenix Dynamometer 280kW Eddy Current Absorber, coupled with high-speed Cotta transmission

with gearbox ratio of 22.5:1, the system is capable of sustaining torques of 60Nm at 45,000RPM and 30Nm at 90,000RPM (currently under commissioning).

ABB 315kW 3,000RPM Motor with ABB ACS880 Speed Controller

FLIR SC7600 MWIR Camera (InSb Sensor)

The camera is mounted on high-precision X-Y-Θ system, which allows movement of 300mm, 300mm and 360 degrees respectively. The system also includes AST CALsys 500 Black Body, suitable for temperature range of 50-500 ºC.

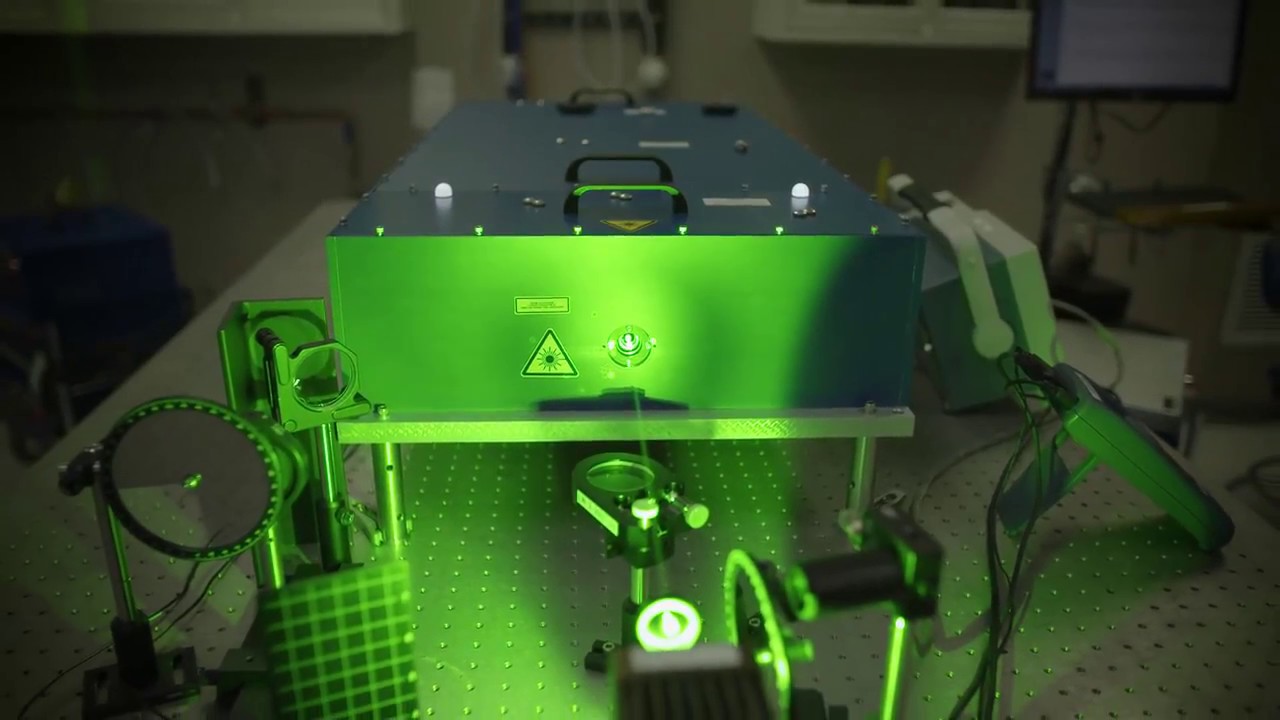

Particle Image Velocimetry System

includes IDT Y7-S1 High Speed Camera, LaVision Aerosol Generator and AMTRON LS453 Laser Diode System.

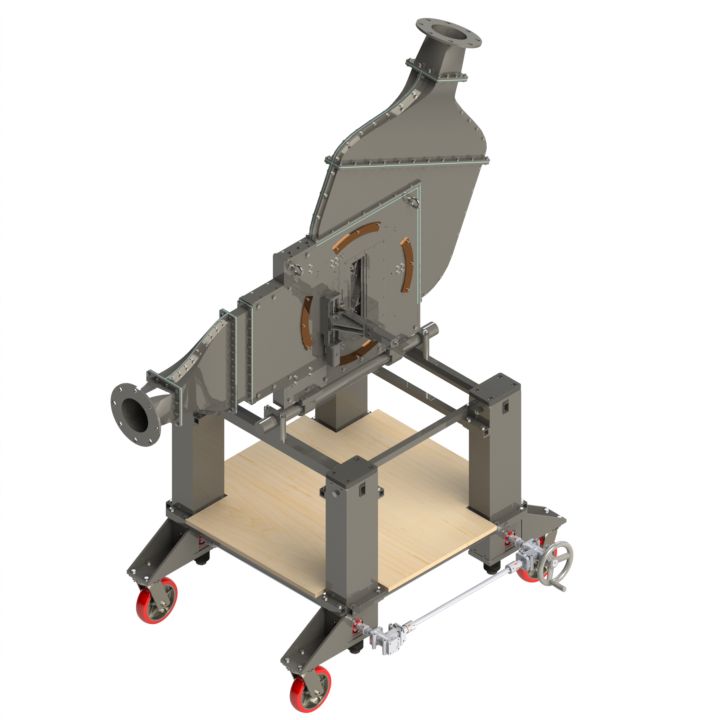

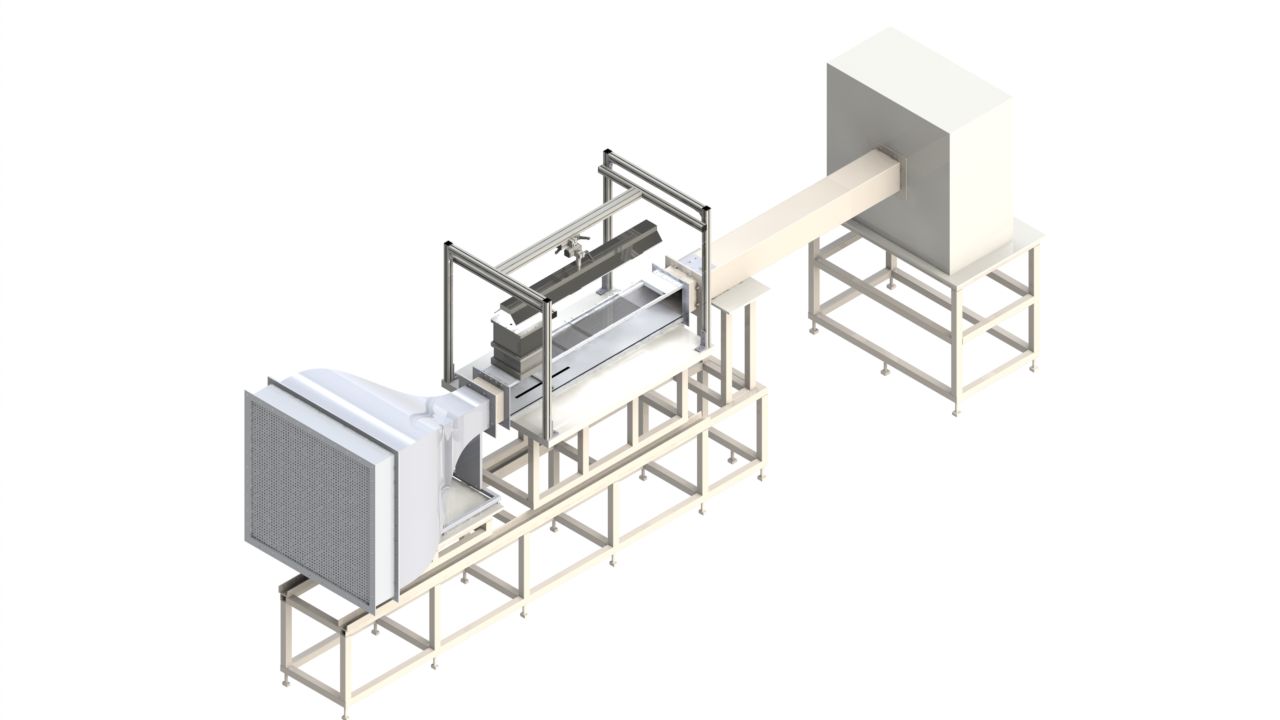

Micro-Turbine Test Facility

Includes continuous closed-loop hot transonic cascade, capable of characterizing the aero-thermal performance characteristics of turbine profiles and cooling schemes (currently in final stages of assembly); and continuous closed-loop hot rotating rig, capable of gauging the performance of an entire turbine stage (currently in advanced stages of design).

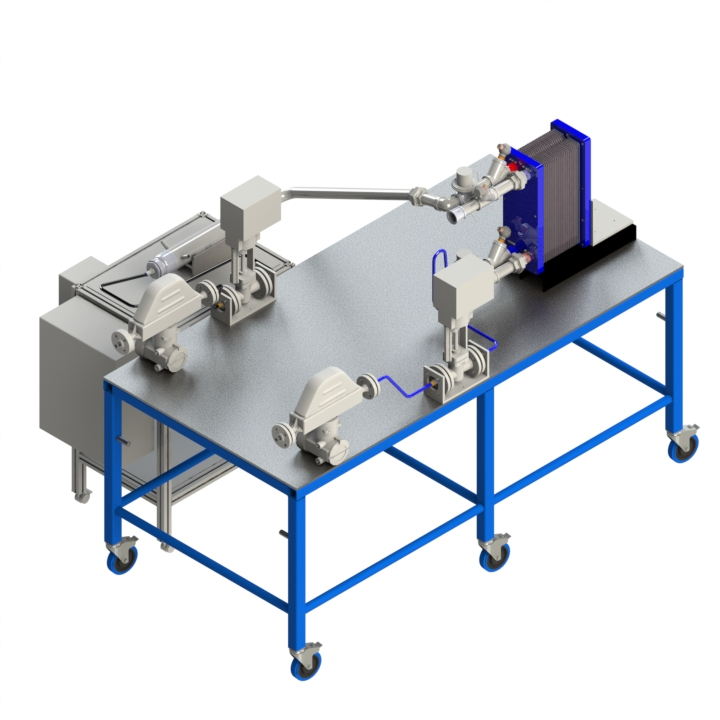

Heat Exchanger Test Facility

Allows for evaluation of aerothermal performance (including the effect of acoustic excitation) for various compact heat exchangers. The rig features 24kW OSRAM electric heater, pre-polarized free-field microphone (with high temperature pre-amplifier), separate mass flow controllers for cold and hot side sides, and temperature / pressure drop acquisition system.

Aero-Acoustic Wind Tunnel Facility

Used for studying novel heat exchanger geometries. Features interchangeable side wall for pressure distribution measurements via Scanivalve DSA3217 Pressure Scanner and thermal performance measurement via liquid crystal thermography.

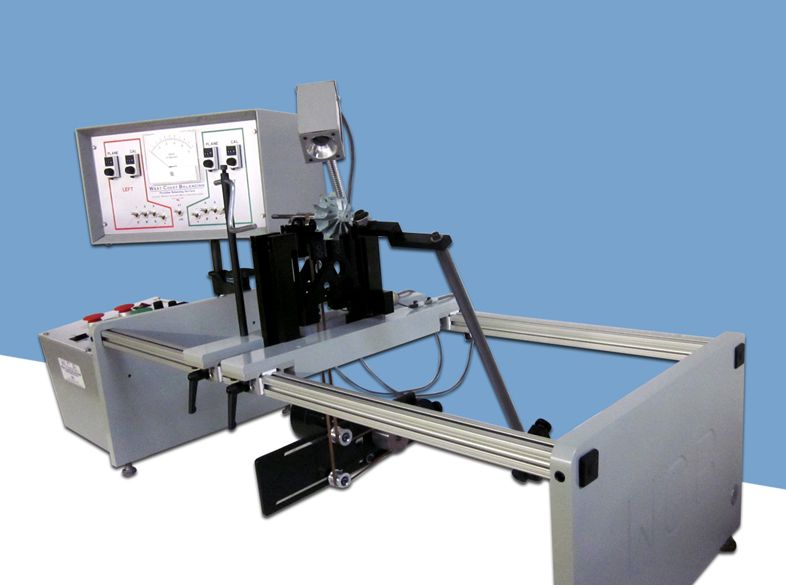

West Coast WCB-30 Bench Balancing Rig

West Coast WCB-30 Bench Balancing Rig – with balance speed range of 500-2500RPM.

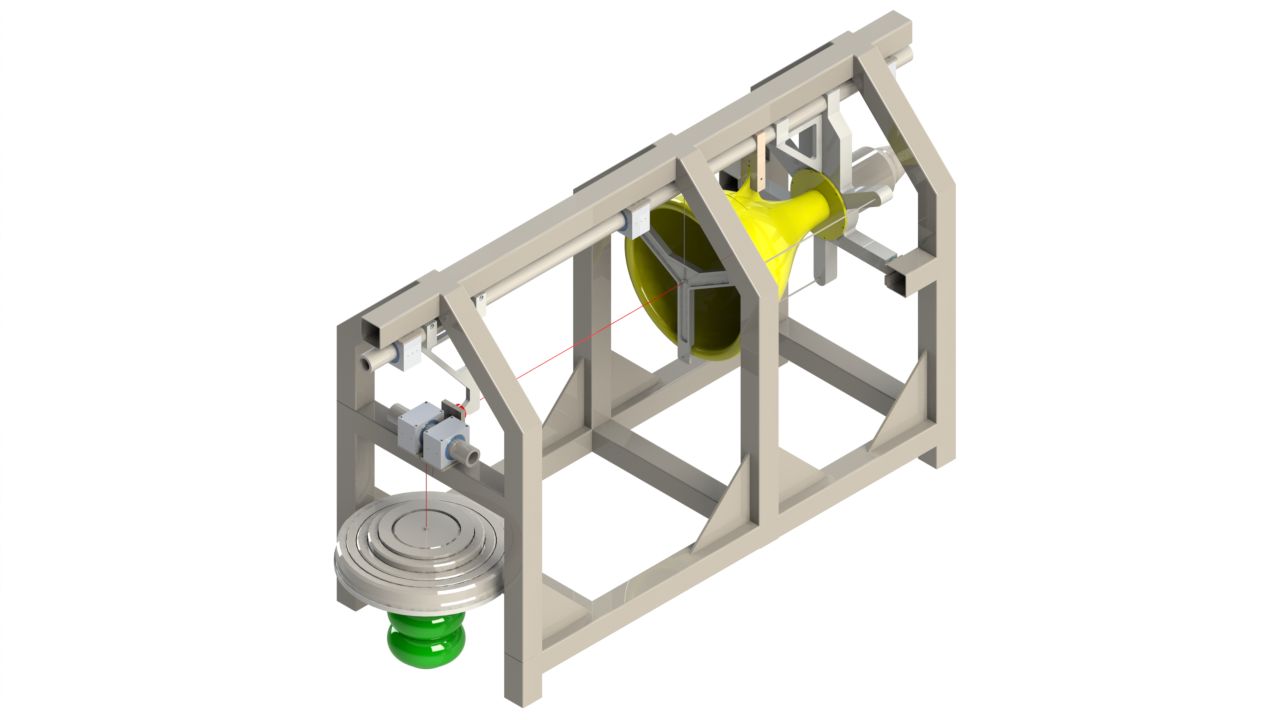

Micro-Engine Test Stand

Micro-Engine Test Stand – allows for performance studies for small-scale gas turbine engines with thrust ratings of up to 2000N (currently in advanced stages of design).

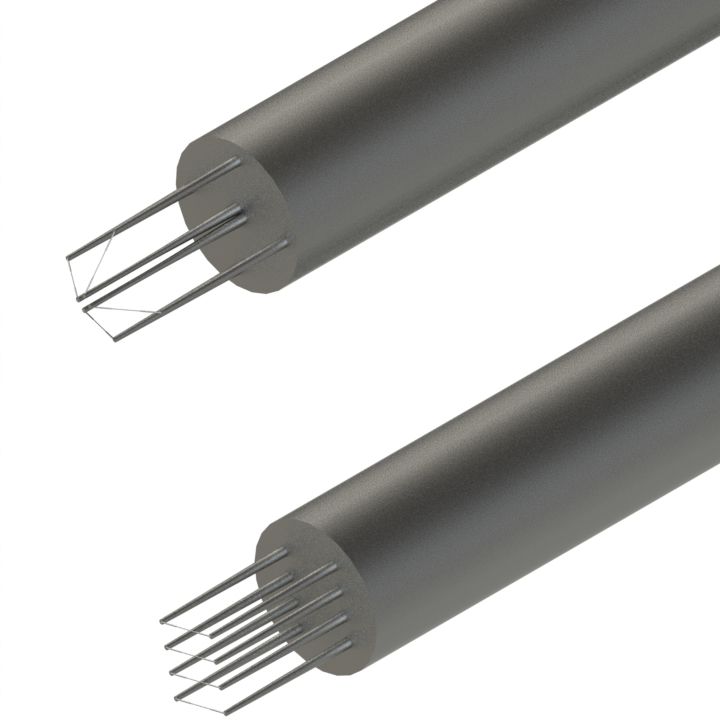

Hot-Wire Probe Manufacturing and Calibration Facility

The laboratory has all necessary tools needed to manufacture, repair and calibrate custom-made hot-wire anemometry probes. The capabilities include AA Lab Systems AN-1003 CTA Anemometry System, Orion Pulse 150i Micro Pulse Arc Welder and Microscope, transonic heated calibration jet, electroplating station and ultrasound cleaning bath.

Sensor Calibration Services

In addition to hot-wire calibrating jet, the laboratory also has high-precision pressure gauge system, heated oil bath and 1000Hz acoustic calibrator that provide calibration capabilities for pressure transducers, thermocouples and microphones respectively.

LC PRO Liquid Polymer 3D Printer

LC PRO Liquid Polymer 3D Printer – features build volume of 470 x 240 x 340 mm and layer thickness of 50 micron.

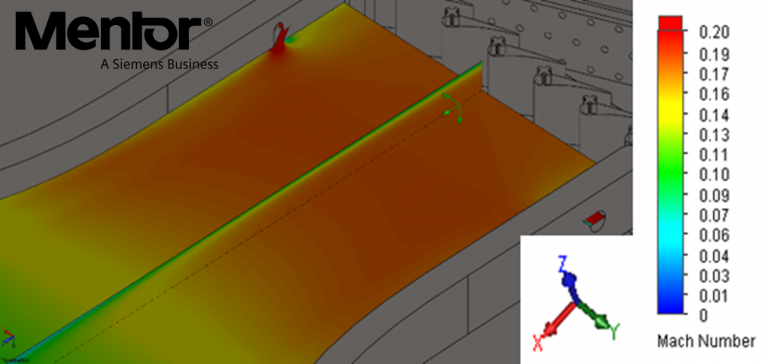

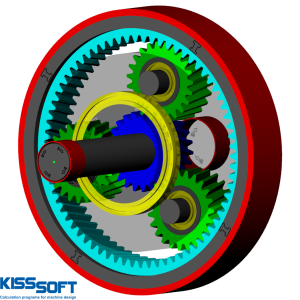

Simulation and Analysis Capabilities

The laboratory staff is skilled with range of high-end simulation and analysis tools and provides numerical services in FloMASTER, FloEFD, GasTurb, KISSsoft, KISSsys, COMSOL Multiphysics, ANSYS and FLUENT.

CNC – DVF5000 with FANUC 31iMB5

CNC – DVF5000 with FANUC 31iMB5 – 5 Axis Simulation